The stamp mill and feeder here at Laws Railroad Museum and Historical Site were built by the Joshua Hendy Machine Works in San Francisco California. . Joshua Hendy came to this country from Scotland in 1836 and learned the machinist's trade. In 1851 at the age of 33 Joshua traveled to California and worked in San Francisco until 1852 when he had saved enough money to build a saw mill on the coast near Fort Ross. In 1855 he returned to San Francisco to manufacture parts for mills. By the 1860's the Joshua Hendy Machine Works was also making parts for mining and milling equipment.

Joshua soon learned that most of the damage done to stamp mills occurred ‘when the operator fed either to much ore into the hopper, which jammed the mill, or few to little, which allowed the stamp heads to hit the mortar base without the cushion of the ore, thus breaking the heads. Unfortunately, mosf mill workers of the day were either inexperienced or drunkards, very few men wanted to spend their day shoveling ore into a dirty deafening monster of a machine. To solve this problem Joshua invented, patented and started producing the Challenge Automatic Ore Feeder for stamp mills. Joshua made improvements and brought out other patents. Soon he controlled the ore feeder market.

Joshua lived in San Francisco and ran the company until his death October 21, 1891. Samuel, Joshua's nephew fook over the business until his death in 1906, the same year that the great earthquake and fire destroyed the manufacturing plant. Samuel's brother John took over and moved the plant to Sunnyvale California. The Joshua Hendy Iron Works operated in Sunnyvale until 1956 when the business sold to Westinghouse Corporation. Westinghouse still has a facility there today.

|

|

|

|

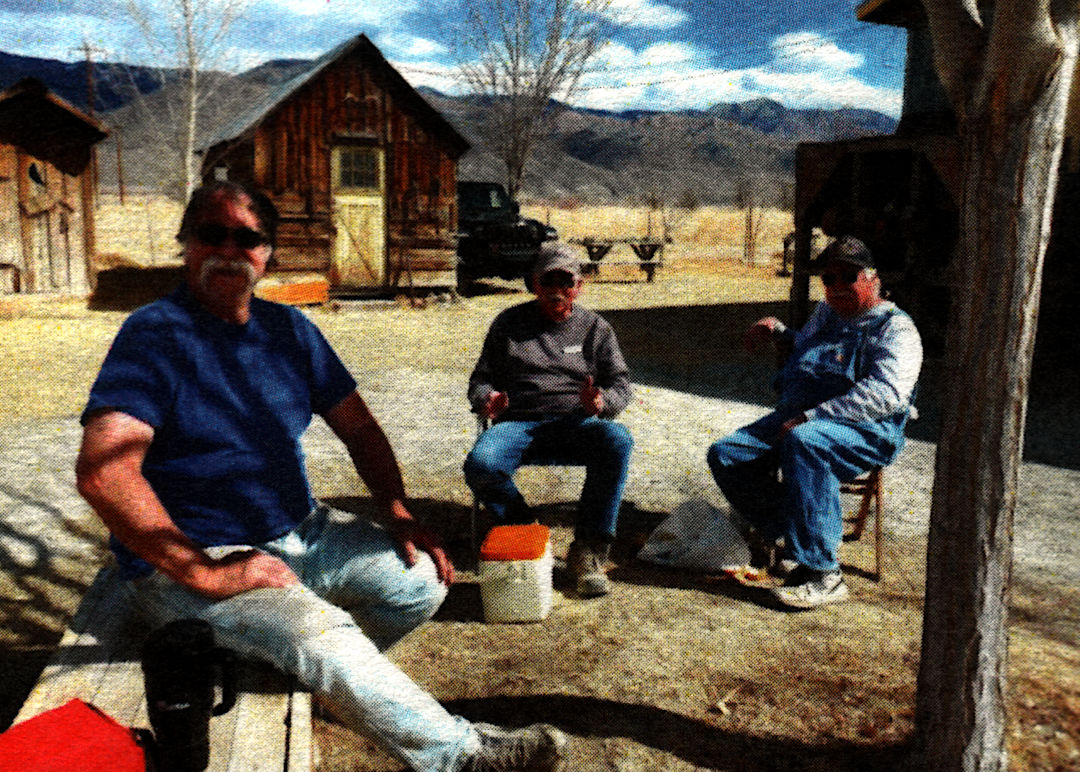

| Top left - Poleta Mine & Miling Company display building. Bottom left - Brad, Jay, and Ron working closely with Roger (out of sight and actually working). Right - Side view of stamp mill and feeder. | |

|

Poleta Dispatch: "Things have been active at the Poleta Mine and Mill. Mr. Smart has volunteered to run the mill. Mr. Ciabineles running the mine. This all took place after the superintendent was called back East. Everyone agreed that he didn't know much about mining or how to run a mill anyway. The consensus was that when he opened his mouth he was full of what makes grass grow. With the superintendent gone we all took Sunday to celebrate at the saloon. The ladies on the line all agreed that they were glad he was gone and that they wouldn't miss that skinflint. We are all glad that scallywag is gone. Everyone left the saloon in good shape and showed up Monday for work. We haven't seen much of Mr. Bradbury. He has been very busy working on electricity problems at the lower levels and the rises. Mr Keehn has been promoted to hoist operator and is the best we've ever had. We haven't had any accidents and he always stops the cage even with the tracks. It is much easier to move the ore car in and out. Mr Morefield installled the post and beam for the trommel shed. The new mucker, Mr Derrybery and Mr Keehn mnufactured a shaft for the pully belt for the trommel. Mr Derryberry seemed to fit in with the crew. I am sure he will be promoted to the blacksmith shop soon. He is energetic and hard working and he doesn't drink. He completed a water tub to show the young whippersnappers at the school how to pan for gold. All of the Jacks are back to work. They say the tommyknockers have been quiet. Production is up. Values are high. We exceed last year's numbers which should make the investors happy." ~Frank Crampton, Assayer for Poleta Mine and Milling Company |

|

Poleta Dispatch: "Production is still up, values are high. Mr. Bob Bradbury reports he saw a different type of material on a face in level 3. He asked me to inspect and upon close examination, it turns out to be a load of complex sulfate material. It will be a bit more work to mill and requires to be roasted before further processing. The material’s assay stands with 1⁄2 ounce per ton. We are going to stockpile the material until we develop a feasible process. Until then we’ll continue to mill the loose friable material. Stay tuned for more news.

~Frank Crampton Jr., Assayer for Poleta Mine and Milling Company |